Call Us08045803802

Showroom

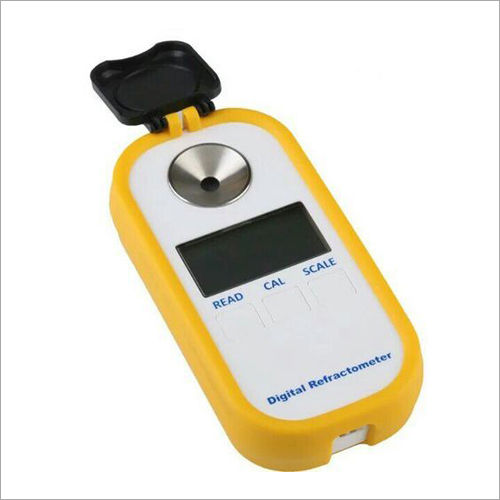

The Digital Refractometers are utilized to measure the refractive index of solid, liquid, geland others. They are also used to determine the samples concentration. These have several operative benefits as the analytic modalities. They are inexpensive and offer rapid measurement is and accurate quantitation.

The Aerosol Food and Beverages Testing Instruments are utilized to test the antimicrobial products. These are valuable for determining the effect of antimicrobial mediators on microorganisms. They are of utmost use and ensure precision and accuracy in all possible aspects.

Refractometers are the portable instruments that are widely used in food processing and liquid beverage industries to measure the sugar content and the concentration of the solution to improve the production quality.

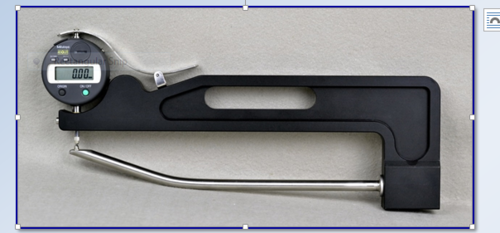

The Bostwick Consistometer is a widely preferred choice that is suited for measuring the flow rate as well as consistency in several products. It can be used on many viscous materials such as salad dressings, paints, sauces, cosmetics and chemicals.

Torque Testers are the testing instruments to measure the opening and closing torque of a screwing caps that are placed on the plastic bottles of water, juice, soda and other beverage drinks.

Indoor Air Quality Monitor is used for different analysis. This is demanded for performance monitoring of HVAC system, air quality engineering study, mould investigation and comfort assessment. This is used at Airport lounges, malls and shopping offices.

Portable analyzers have a substantial share of the Nova Analytical product line. They are apt for temporary as well as sporadic analysis of individual sample points. They have repeatable accuracy and are suited for the offshore applications.

|

PARISA TECHNOLOGY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry